Let’s be honest. The old way of doing business—take, make, dispose—feels increasingly, well, old. It’s a linear path that hits a dead end, often in a landfill. Meanwhile, the concept of a circular economy, where waste is designed out and materials are kept in use, can seem like a beautiful, abstract ideal. Something for green startups, maybe, but not for established companies with legacy systems.

Here’s the deal: that gap between the traditional and the circular? It’s where the next wave of innovation, resilience, and honestly, profit, is hiding. Integrating circular principles isn’t about scrapping your entire model overnight. It’s a strategic retrofit. A series of deliberate, smart shifts that build a business that’s not just sustainable, but fundamentally more robust.

Why Bother? The Compelling Case for Circularity

Sure, regulatory pressure and consumer expectations are real drivers. But the core motivation is simpler: risk and cost. A linear model is vulnerable. It depends on constantly extracting new, cheap raw materials—a supply chain gamble if there ever was one. Circular strategies, by contrast, build in buffers. They create value from what you already have.

Think of it like maintaining a classic car. You don’t throw it away when a part wears out. You repair it, refurbish it, or find a creative new use for an old component. The car gains character and history, and you avoid the massive outlay for a new vehicle. Your business’s material flows aren’t so different.

The Pain Points of Sticking to Linear

Before we dive into solutions, let’s name the headaches. The linear model is fraught with them:

- Volatile commodity prices: Your bottom line gets yanked around by global markets you can’t control.

- Waste disposal costs: They’re not getting cheaper. Landfill taxes and emissions penalties only go up.

- Broken customer relationships: The transaction often ends at the checkout. That’s a missed opportunity for recurring revenue and loyalty.

- Innovation stagnation: When “new” just means more of the same virgin material, you’re not really solving deeper problems.

Mapping the Integration: Where to Start

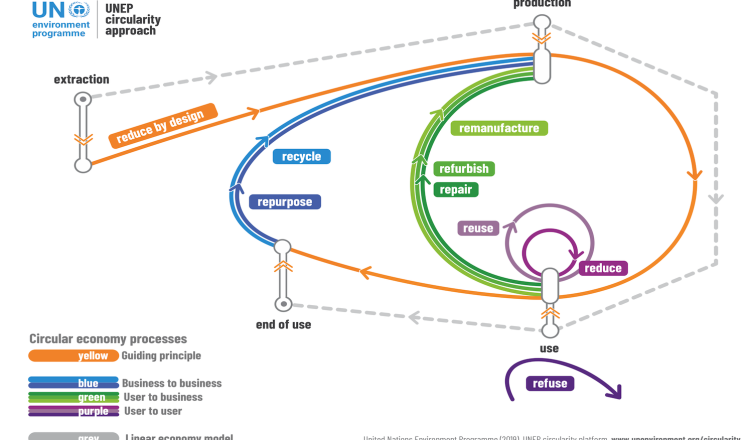

This isn’t about a vague “green initiative.” It’s a operational rethink. You can start small. The key is to look at your business through two new lenses: product life extension and material cycling.

1. Rethink Design & Sourcing

Everything begins here. Circular integration means asking different questions at the design stage: “Can this be easily repaired?” “How do we get this back?” “What happens to this component at end-of-life?”

This is where design for disassembly comes in. It’s like designing a puzzle that can be taken apart and reassembled. Use standardized screws instead of permanent glue. Mark material types on components. This upfront thinking makes everything downstream—repair, refurbishment, recycling—dramatically easier and cheaper.

2. Shift from Product to Service (The Performance Model)

This is a powerful one. Instead of selling a light bulb, you sell illumination. Instead of a carpet, you sell floor-covering services. You retain ownership of the material assets. Suddenly, your incentive aligns perfectly with durability, efficiency, and recoverability. You want that product to last as long as possible and to get every bit of value from it at the end. It transforms your relationship with the customer, too, from a one-time sale to an ongoing partnership.

3. Build Reverse Logistics

If “forward logistics” is getting your product to the customer, “reverse logistics” is the often-ignored journey back. For a circular model, it’s the circulatory system. You need a plan to take back used products, packaging, or off-cuts. This could be a take-back program, in-store drop-offs, or partnerships with specialized recovery firms.

Yes, it’s a new cost center—at first. But it also becomes a new source of feedstock. Those returned items are not trash; they’re tomorrow’s raw materials, often secured at a lower cost and with a lower carbon footprint than virgin ones.

A Practical Snapshot: Circular Strategies in Action

| Traditional Model Tactic | Circular Integration Approach | Business Benefit |

| Selling a piece of machinery | Selling “machine hours” with full maintenance & upgrade service | Predictable recurring revenue; stronger client lock-in; asset control |

| Using virgin plastic in packaging | Designing packaging from 100% recycled (or easily compostable) materials | Reduces exposure to oil price spikes; meets ESG goals; appeals to conscious consumers |

| Landfilling manufacturing scrap | Creating a secondary product line from “waste” material | Turns a disposal cost into a revenue stream; fosters innovation |

| End-of-life product is customer’s problem | Instituting a buy-back or trade-in program | Secures valuable materials; builds customer loyalty for the next purchase |

The Human Hurdles: Culture and Mindset

Alright, so the processes make sense. But the biggest barrier isn’t technical—it’s cultural. You’re asking sales teams to sell services, not just products. You’re asking finance to value long-term asset health over short-term sales spikes. You’re asking designers to care about the end-of-life, a phase they never had to think about before.

Communication is everything. Frame it not as a constraint, but as a creative challenge. As a way to future-proof the company. Celebrate teams that find ways to eliminate waste or recover value. Make it tangible—show them the pile of material saved from landfill, or the customer testimonial about the repair service.

A Final, Thought-Provoking Point

Nature doesn’t have a landfill. In a forest, the “waste” from one system—fallen leaves, decaying wood—becomes the nutrient input for another. That’s the elegant, resilient system we’re trying to mimic. Integrating circular economy principles isn’t just an ethical add-on. It’s a step towards building a business that operates more like a natural ecosystem: adaptive, resourceful, and enduring.

The journey from linear to circular is just that—a journey. It starts with a single, deliberate loop. Maybe it’s a take-back program. Maybe it’s a redesigned product for easier repair. The point is to start closing the loop somewhere, anywhere. Because in the economy of the future, the most successful businesses won’t be those that extract the most, but those that make the most of what they already have.